Beer Brewing 101

- Introduction to Brewing

- Understanding Brewing Ingredients and Equipment

- Mashing and The Boil

- Clarification and Carbonation

- Recipe Formulation

- Troubleshooting Brews

- Beer Styles & Taste Profile

- Advanced Brewing Techniques

- Homebrewing Equipment

- Craft Beer Business Basics

Fermentation

Controlling Fermentation in Beer Brewing

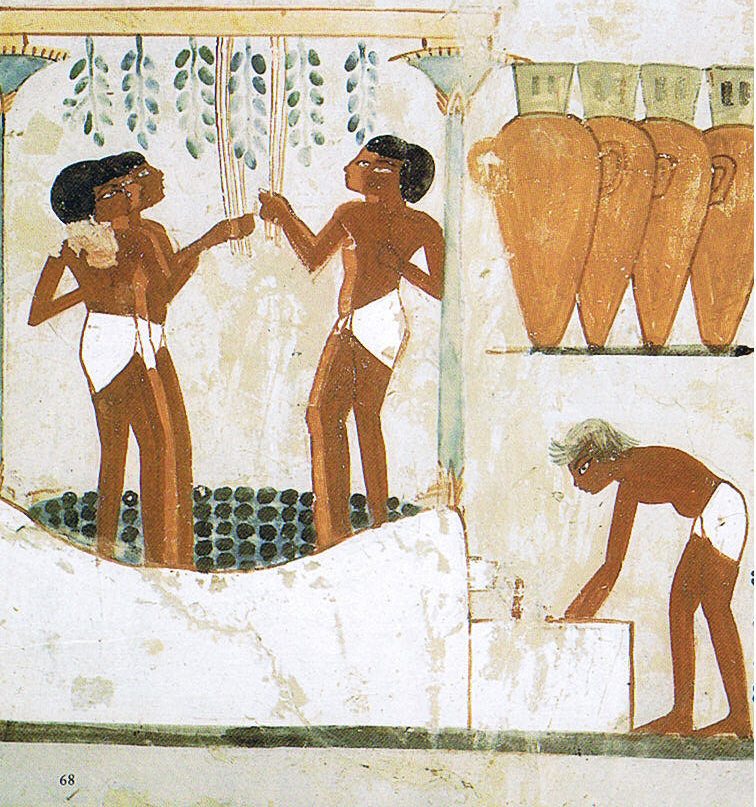

Food produced by a method converting substrates to fermentation end products.

Fermentation is a critical stage in the beer brewing process. It's where the magic happens - where yeast consumes the sugars in the wort and produces alcohol, carbon dioxide, and a range of flavors that define the beer's character. Controlling this process is key to brewing beer that tastes great and meets your expectations. In this article, we'll explore the importance of temperature control, the different types of fermentation vessels, and how to monitor fermentation.

Temperature Control

The temperature at which fermentation occurs has a significant impact on the flavor of the beer. Different yeast strains have different optimal temperature ranges, and fermenting outside of these ranges can lead to off-flavors or stalled fermentation.

To maintain the right temperature, you can use a temperature-controlled fermentation chamber, such as a modified fridge or freezer. Alternatively, you can use a heat wrap or brew belt to warm your fermenter in a cool environment, or a wet towel and fan for evaporative cooling in a warm environment.

Fermentation Vessels

The vessel you choose for fermentation can also affect your brew. The two main types of fermentation vessels are carboys and buckets.

Carboys, which can be made of glass or plastic, are a popular choice due to their narrow neck, which helps limit the beer's exposure to oxygen. However, they can be difficult to clean and move around.

Buckets are easier to clean and handle, and they often come with a spigot for easy transfer of the beer. However, they can be more prone to oxygen exposure, and scratches in the plastic can harbor bacteria and wild yeast.

Stainless steel fermenters are another option. They are durable, easy to clean, and resistant to oxygen exposure, but they are also more expensive.

Monitoring Fermentation

Monitoring the progress of your fermentation can help you identify any potential issues before they become major problems.

One way to monitor fermentation is by taking gravity readings with a hydrometer or refractometer. This allows you to track the sugar consumption by the yeast and estimate the alcohol content of your beer.

You can also monitor the activity of the airlock. A vigorous bubbling indicates active fermentation, while a lack of activity could mean that fermentation has stalled.

Secondary Fermentation

Secondary fermentation is an additional step that some brewers use to clarify their beer or add additional flavors. After the primary fermentation is complete, the beer is transferred to a second fermenter, leaving behind the yeast and sediment.

While secondary fermentation can improve the clarity and stability of the beer, it also carries a risk of oxygen exposure and contamination. Therefore, it should be done with care and is often reserved for beers that benefit from extended aging.

In conclusion, controlling fermentation is a vital aspect of brewing that can significantly influence the final product. By understanding and managing factors like temperature, choice of fermentation vessel, and monitoring techniques, you can ensure that your fermentation process runs smoothly and produces delicious beer.